Call us

01900 816000

Head Office

Risehow Hydraulics Centre, Flimby, Maryport Cumbria, CA15 8PA

01900 816000

Risehow Hydraulics Centre, Flimby, Maryport Cumbria, CA15 8PA

World-first technology being developed in the UK to improve performance and safety for industries around globe on course for trials in early 2021

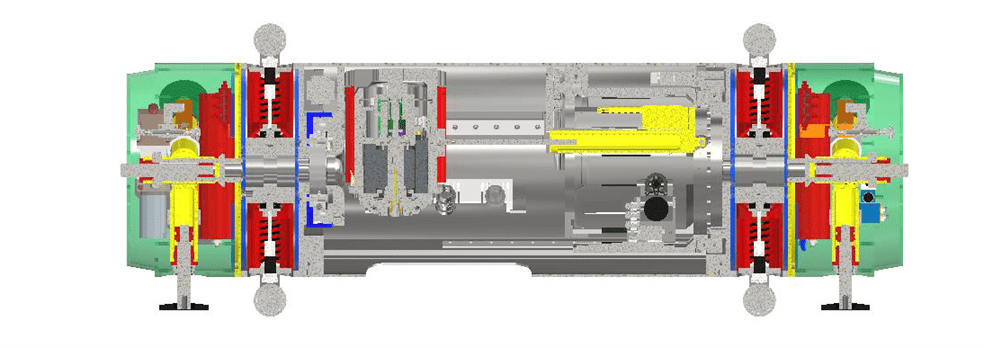

One segment will carry the FSW machine and a steel patch dispenser, with the other segments carrying the navigation, control system, communications, NDT (non-destructive testing) and power storage/generation payloads.

On entering the pipe segment containing the pre-identified defects, the FSWBot will stop, then slowly advance until the FSW system is in place over the defect. It will then lock itself in place and confirm that it is correctly located to perform the repair.

An onboard turbine in a duct within the FSWBot will harvest energy from the oil flow within the pipe to augment any power cells carried on the system, with the duct providing through flow in the pipe.

The development of the first ever FSWBot, Friction Stir Welding Robotic Crawler for internal repair and refurbishment of pipelines, is designed to transform the way industries deal with pipeline issues.

Led by Forth Engineering in Cumbria, the FSWBot project has been attracting attention from around the world ever since being first showcased in Aberdeen last November.

Forth Engineering is working with consortium members TWI, J4IC, Innvotek and LSBU on the project which will have a major positive impact on safety within the industry.

Sponsored by Innovate UK, the project seeks to integrate several state-of-the-art technologies including friction stir welding, milling, patch deployment and ultrasonic NDT, onto a robotic system which can be deployed to conduct repairs on pipelines without the need for the pipeline to be closed down for the duration of the repair.

Once energised, the FSW unit will deploy a milling tool to cut away the corroded area and prepare a pocket in the pipe wall into which a steel patch will be dispensed.

The FSW unit will then weld this patch in place and deploy the milling system again to ensure that the patch is flush with the pipe wall and will not initiate turbulent flow, nor impede the passage of subsequent cleaning or inspection PIGs.

FSWBot will then deploy NDT packages to inspect the weld for quality assurance before unclamping and moving downstream to repeat the process on any further defects.

The FSWBot is attracting interest from different industries around the world and the consortium wants to hear from companies and sectors which might have an interest in the system.

Head Office

Risehow Hydraulics Centre

Flimby

Maryport

Cumbria

CA15 8PA

T. 01900 816000

E. info@forth.uk.com

Mon – Friday: 8 am – 5 pm.

Saturday: 8 am - 1:30 pm.

Sunday: CLOSED.

Trade Call Out service: 24 hours

Here at Forth, we dedicate ourselves to engineering excellence.

We work closely with industry leaders in a wide range of sectors to help them deliver innovative and ground-breaking solutions to complex problems.